- Welcome To Shree Bhagwati Machtech India Pvt. Ltd.

- +91 9898070475

- [email protected]

Pellet Extrusion Spheronization, a promising pelletization technique

Fluid bed equipment- Fluid bed dryers

December 25, 2019

Get Different Types of Mixers for Solids – Dry and Wet.

February 4, 2020Pellet Extrusion Spheronization, a promising pelletization technique

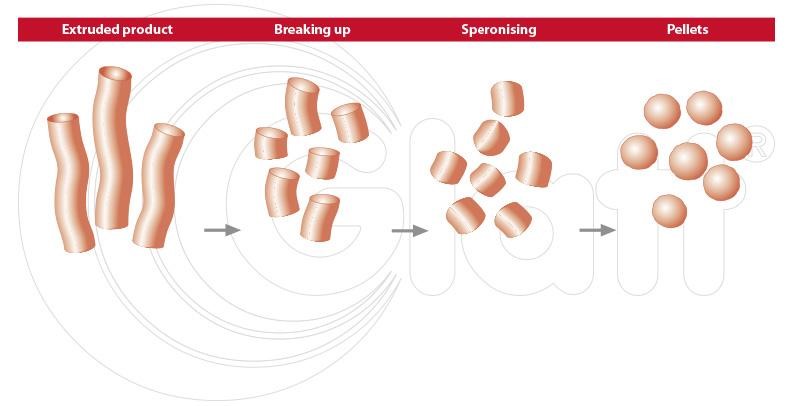

The production process of pellet includes extrusion, granulation, spheronization, drying, mining, etc. Out of all the techniques, the pellet extrusion spheronization is considered as a promising and innovative pelletization technique. Let us understand why by moving in the detailed discussion of the same.

Pellets are manufactured using the extrusion and spheronization since a long time. Industries have been using this old technique till date for manufacturing pellets through agglomeration.

Pellet extrusion spheronization process includes:

- Powder mixture moistening

- Extrusion and agglomeration

- Spheronization method for rounding the pellets

- Drying the pellets (finished product)

Source: GLATT

Benefits of utilizing Pellet Extrusion Spheronization

1: It utilizes the high loading capacity for producing small-sized spheroids

2: The Spheroids that are produced using pellet extrusion spheronization are uniform in size. It has a narrow size distribution and unusual flow characteristics.

3: As the process produces uniform spheroids, a successful coating is applied.

4: Spheronization results in blending and formulation in single unit dosage for pellets that are composed of different drugs.

5: It helps with free distribution and offers flawless flexibility.

6: The active ingredients are more safe and efficient with spheronization technique.

7: The bioavailability of the drugs is enhanced with spheronization process.

Liquid Mixing Plant offers the following products for the Pellet Extrusion Spheronization

- Sieving Granding Vibro Sifter

- Axial Extruder

- Basket Extruder

- Fluid Bed Dryer

- Sigma Mixer with mixer z blade

- Sigma Mixer with extruder screw

- Spheronizer

Why us?

Shree Bhagwati Liquid Mixing Plant manufactures and exports the top-class liquid mixing machines including the laboratory and pilot-scale equipment, vacuum mixer dryers, CIP WIP bunker washing systems, etc. The unit takes into account flawless quality and innovation for designing and producing world-class liquid mixing machinery that can be further utilized by the pharmaceutical and other industries.

You can reach them at https://localhost/wpsin or can also place your machinery query at [email protected].