- Welcome To Shree Bhagwati Machtech India Pvt. Ltd.

- +91 9898070475

- [email protected]

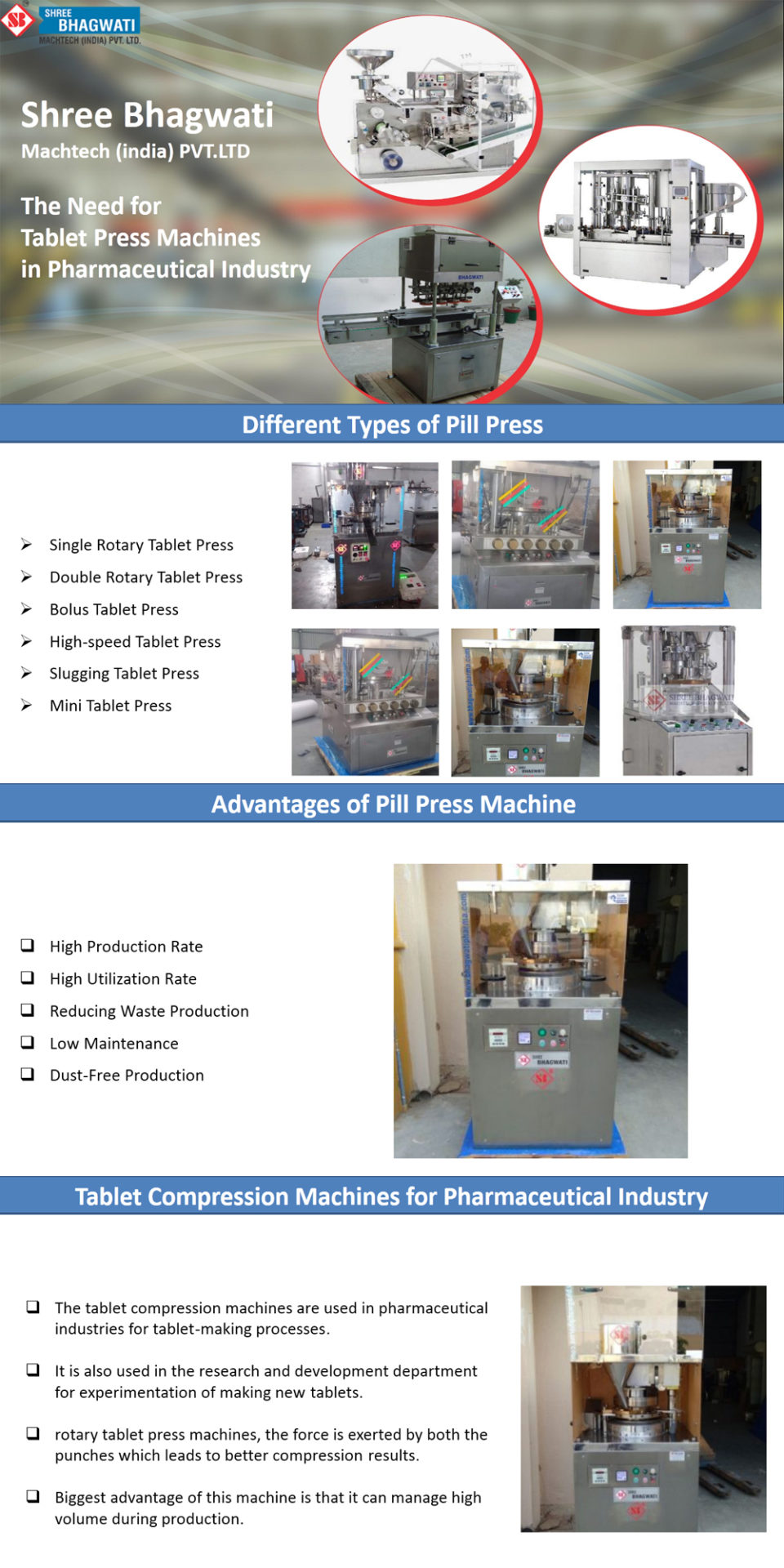

The Need for Tablet Press Machines in Pharmaceutical Industry

Working Principle of Automatic Tablet Coating Machine

March 27, 2021Tablet press machine helps to compress the powder into tablet form in various shapes and sizes depending upon the need of the market. Due to constant growth in the pharma industry, it becomes important to enhance the working procedure. In current times, the rotary tablet compression machine is one of the most significant machines for the pharmaceutical industry.

With the evolution of technologies, advanced improvements have also been made in the design of tablet presses. The process of tablet making involves the usage of dies and punches which help to infuse the powdered material into solid tablet forms.

The pill press is categorized into different types such as single rotary tablet press and double rotary tablet press. This is also known by the names bolus tablet press, high-speed tablet press, slugging tablet press, and mini tablet press.

Lab Scale Mini Tablet Press – No Of Station 8, 10, 12

Single Rotary Tablet Press – 16, 23 Station

High Speed Tablet Press – 20, 27, 30 Station

Advantages of Pill Press Machine

The lab tablet press machine has various advantages that make it most opted in industries. A brief description of its advantages are as mentioned below:

- High Production Rate

- High Utilization Rate

- Reducing Waste Production

- Low Maintenance

- Dust-Free Production

High Production & Utilization Rate

Pill press machines have a high production rate. These tablet press machines have excellent functionalities like a spring mechanism that improves its working. The square tubular design gives a high utilization rate and thereby increases the production rate in the organizations. As a result, it also includes parts that are critical and help in producing contamination-free tablets.

Reducing Waste to Minimum

The rotary tablet press is a covered machine with a glass covering. The outer covering of the machine helps in reducing the waste produced during tablet production. Along with the rotary tablet press machine’s covering, dust-free production becomes easy.

Low Maintenance

The tablet compression machine is an impactful equipment that needs low maintenance. Due to its small and rational size the machine is easy to operate and ideal for small batch production. These lab tablet press machines used are made from stainless steel. Due to its CGMP standards compliance and been made from SS material, it becomes easy to clean and maintain the machine. With proper tooling and maintenance, this machine can deliver the best results as needed in the industry.

Operator Friendly

The pill press machine is easy to use for operators. Due to the presence of simple functionalities on the machine, the machine is safe for the operator. It runs noiselessly and smoothly when kept properly maintained.

Tablet Compression Machines for Pharmaceutical Industry

The tablet compression machines are used in pharmaceutical industries for tablet-making processes. It is also used in the research and development department for experimentation of making new tablets. The tablet press is also used in other similar industries that form tablets such as herbal.

In rotary tablet press machines, the force is exerted by both the punches which leads to better compression results. The biggest advantage of this machine is that it can manage high volume during production. The efficiency and high accuracy in the formation of tablets is the reason that makes these slugging tablet press machines the most proficient in the industry.

With years of experience, Shree Bhagwati Machtech offers the best tablet compression machines that give the best result for industrial applications. By opting for the right tablet presses, one can gain the exact output as needed by the organization.