- Welcome To Shree Bhagwati Machtech India Pvt. Ltd.

- +91 9898070475

- [email protected]

Fluid Bed Dryers: Multifunctional Machine

Shree Bhagwati Machtech – About Processing and Packaging Machinery – USA , UK , AFRICA Demand

March 25, 2021

Double Cone Blender vs. Octagonal Blender vs. Blender

March 26, 2021Nowadays, Science & Technology have grown so vast. Humankind has made work proficient with the help of machinery.

Almost, engineering-led to make our life smooth and easy-going by innovating new equipment for our daily life.

Fluid Bed Dryers (also called Fluidized bed dryer) is one of the well-known machine names that are used extensively in various industries. So, let’s acknowledge the various criteria of this Fluid Bed Dryer for better understanding.

What is Fluid Bed Dryer

Fluid Bed Dryer or Fluidized Bed Dryer is an equipment that is mainly used for reducing moisture.

Where it is used?

It is widely used in pharmaceutical companies or chemical companies for the reduction of moisture from granules and powder.

The equipment works on the fluidization of the feed materials.

Where is the need of the Fluidized Bed Dryer?

Fluidized Bed Dryer needed For drying of various materials such as

- Coal

- Tablet

- Fertilizer

- Powder

- Granules

- Plastic material

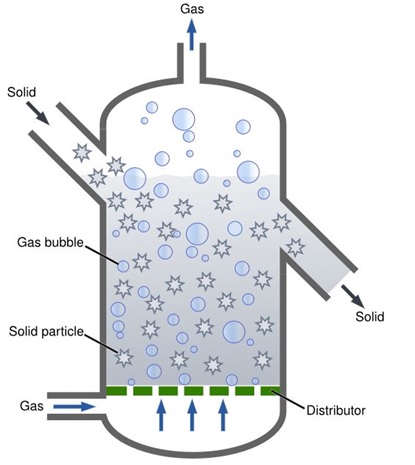

Principle of fluidization:

- If gas is allowed to flow through a bed of particulate solids of velocity greater than the settling velocity of the particles, less than the terminal velocity of pneumatic conveying, and equivalent to the fluidization process’s minimum velocity (V mf), in such cases the solids get partially suspended towards upward moving gas.

- The stream of gas helps in neutralizing the force of gravitation caused due to the particle’s weight and thereby enabling the solid-state to dissolve.

- In conclusion solids and gas get diffused and get converted into liquid form and the remaining solids are known as fluidized.

Design & Construction of Fluid Bed Dryer

Construction:

- Stainless steel or plastic is the main material used for manufacturing the dryer.

- The bottom of the dryer contains a detachable bowl.

- Construction:

- The manufactued bowl contains penetrated bottom.

- Heat exchangers are connected to warm up the air.

- Construction:

- Bag filters are placed above the drying bowl for the recovery of fans.

Working of Fluid Bed Dryer

The wet granules to be dried are placed into detachable bowl.

The hot air flows through the bottom with the velocity greater than settling velocity of granules.

The granule rise and fall back in a random boiling motion.This condition is known as fludized state

The air leaves the dryer by passing through the bags.

Drying stays at constant rate til the resident time for drying is about 40 minutes.

Fluid Bed Dryer Parameters

1. Parameters for Apparatus:

- A plate for distributing the airflow pattern within the body is influenced by the position of the air distribution plate.

Instrument body shape Product and fluidization are improved with an annular foundation. - Instrument body shape Product and fluidization are improved with an annular foundation.

- In the case of a coater or granulator, the nozzle height is essential, the nozzle height is essential. It’s important because the atomized coating solution shouldn’t dry out until it reaches the tablet surface.

- Service with positive and negative pressure.

2. Parameters to Consider During Process:

- With the increase in air temperature of the inlet, drying air temperature also rises parallel. This can also be the opposite for the same. But, since certain products are harmed by high temperatures, such as Ibuprofen, which liquefies at temperatures above 60°C, the temperature of the inlet air can be optimized without affecting product quality.

- During the process, the inlet air should have low humidity as much as possible. Further, dehumidified air is preferred to improve the drying rate.

- To allow effective use of drying air, the airflow rate must be carefully regulated. To ensure successful drying, should have a consistent speed of neither being quick nor being slow.

3. Parameters for Product:

- The moisture quality of the substance at the beginning should not be too high, since this would lengthen the drying period.

- The scale of the batch should be lightweight and designed for practical implementation.

Advantages of Fluid Bed Dryer

- Capital and operating costs are reduced.

- When part of the thermal energy for drying is provided by the internal heat exchanger, high thermal efficiency is normally achieved.

- Excellent gas-particle constant results in high heat and mass transfer speeds, resulting in high moisture removal rates

- Drying time is reduced.

- Used Easily and efficiently.

Disadvantages of Fluid Bed Dryer

- Poor fluidization and flexibility, especially if the feed is excessively wet.

- When organic solvents must be separated during drying, this equipment is not the right option.

- Certain types of fluidized bed dryers have non-uniform product consistency.

- There is a high risk of attrition and, in some situations, fine particle agglomeration.

- Due to the comprehensive recirculation of exhaust gas for high thermal efficiency processing, increased gas handling is needed.

- The need to suspend the whole bed in gas results in high pressure fall, which often results in high energy consumption.

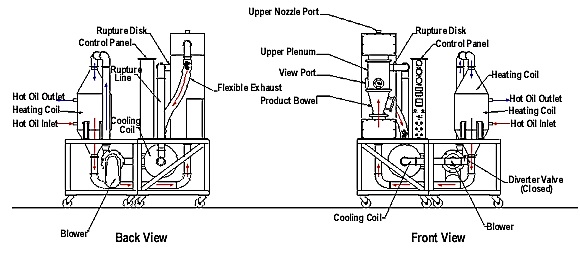

Lab Fluid Bed Dryer

- This equipment is mainly multifunctional laboratory equipment that is flexible and versatile.

- It is used for a number of uses, including curing, granulation, layering, and coating.

- This unit’s control system, which includes a touchscreen interface, is one of the most appealing characteristics.

- It’s vital because it makes the fluidization process much simpler to handle.

Lab Fluid Bed Processor

- Lab fluid bed processor is the top-rated process & widely used in industries.

- Some of the other epic functions provided by the features include strategically placed top spray granulation and bottom spray coating operations.

- Much exciting about this unit is that it is specifically engineered and machined to strict cGMP requirements.

- Fluid-Bed Processors are designed for mixing, granulation, drying or coating and can be used in the pharmaceutical, chemical, food and other industries. Coater and Dryer, Fluid Bed Equipment, Fluid-Bed Granulator and Coater-Combo, Granulator, Multi Function Fluid-Bed Granulator and Coater, Pellet Coater & Dryer